Economic resource and metallurgy thematic group

The introduction of bronze as a material and the subsequent development of metalworking across Europe had a profound impact on the socio-economic structure of communities throughout the period. The innovative technologies, knowledge, and raw materials led to the formation of new networks and the intensification of existing inequalities. The mapping of stone, copper, gold and other raw materials (e.g., amber) used in the Copper and Bronze Ages, combined with data from later periods known from written sources, provides a new basis for understanding resource and exchange networks.

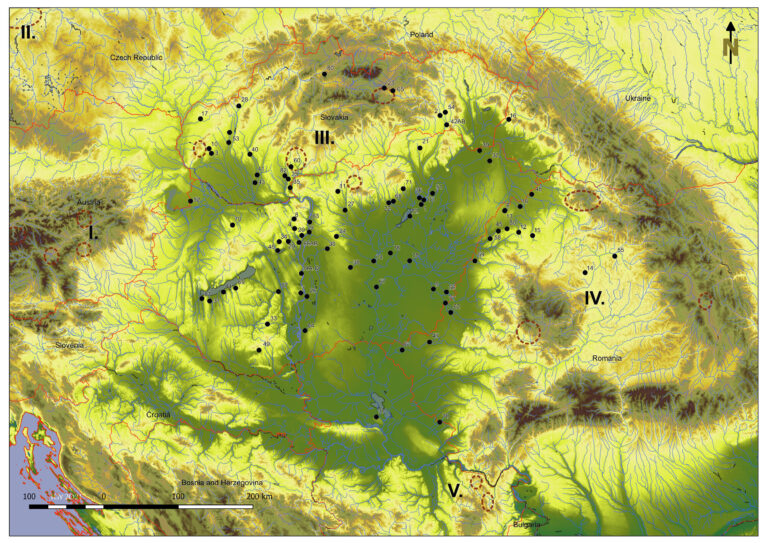

Distribution of Middle Bronze Age casting moulds and mining regions operating/used during the Bronze Age (Ilon 2022)

One of the most dynamic areas of Bronze Age research in recent years has been the question of the trade in copper and tin across Europe. The objective of this project is to continue the traditional archaeological, elemental compositional and production process analysis of copper and bronze jewellery, tools and weapons recovered from the burials and settlements under study. This is achieved through the use of non-destructive neutron methods and destructive archaeometallurgical sampling. By integrating all these data sets, we can explore in greater detail than ever before how and through what mechanisms, the use of bronze transformed the Carpathian Basin and the surrounding region. In addition to the publication of the results of the analyses conducted and those planned, the data will also be included in the thematic database on the archaeometallurgical data of Bronze Age (2500–1500 BC) metal objects in Hungary.

PIXE analysis of a Middle Bronze Age bracelet from Dunavecse at the ATOMKI Heritage Science Laboratory in Debrecen (photo: Zsófia Kertész)

Elemental composition analysis and lead isotope analysis

The X-ray fluorescence analysis of trace elements (silver, cobalt, nickel, arsenic, antimony and bismuth) present in the raw bronze material provides a starting point of identifying potential ore sources, as these elements are also present in the raw copper after the copper ore has been smelted. Beside destructive investigations, non-destructive methods such as PGAA (prompt gamma-activation analysis) and PIXE (proton-induced X-ray emission analysis) are especially valuable for heritage conservation.

Lead isotope ratios (206Pb/204Pb, 207Pb/204Pb, and 208Pb/204Pb) will allow a more precise attribution of copper to specific ore deposits.

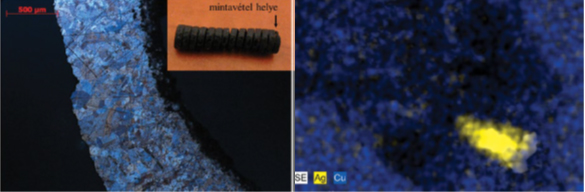

Microstructure analysis

The investigation of the microstructure of bronze objects can provide fundamental information on the production technique, since the bronze casting technology (e.g. cooling rate of the material and post-casting processing) clearly causes visible changes in the grain structure. These analyses help determine whether an object was worked after casting and whether its manufacture involved cold or hot forming. In addition to the examination of fractured samples, non-destructive diagnostics (TOF-ND: high-resolution time-of-flight neutron diffraction) is also important here, as it can be used to examine the crystal structure and phases of the objects.

Bonyhád Biogas Factory, grave 200, Q200J4. (a) Optical microscope image showing the microstructure of a spiral bead under polarized light (magnification: 50x), and (b) elemental map indicating silver enrichment in the corrosion product (SEM–EDX image, magnification 5000x; Kovács et al. 2019, Fig. 4)

Our relevant works on the topic:

- Ilon G.: Kérdések, hipotézisek és feladatok a Kárpát-medence bronzkori öntőformáinak kapcsán. In: Cseh F., Kiss V., Szulovszky J.: A nemes- és színesfémek régészete, története és néprajza a Kárpát-medencében. Készítéstechnikai, archeometriai és társadalomtörténeti megközelítések. Budapest 2021, 35–42.

- Kiss, V., F. Romhányi, B.: Raw material trade and/or itinerant artisans? Data for a diachronic study of the trade in copper raw materials and finished products in the Carpathian Basin. Acta Archaeologica Academiae Scientiarum Hungaricae 74 (2023) 415–436. https://doi.org/10.1556/072.2023.00023

- Kovács R. L., Gyöngyösi Sz., Barkóczy P., Juhász L., Szabó G., Kiss V.: Technológiai megfigyelések kora és középső bronzkori fém tárgyakról (Technological observations of Early and Middle Bronze Age metal objects). In: Vicze, M., Kovács, G, (szerk.): MOMOSZ X, Őskoros Kutatók X. Összejövetelének konferenciakötete, Őskori technikák, őskori technológiák. Százhalombatta 2019, 187–197.

- Szabó, G., Barkóczy, P., Gyöngyösi, Sz., Kasztovszky, Zs., Káli Gy., Kis, Z., Maróti, B., Kiss, V.: The possibilities and limitations of modern scientific analysis of Bronze Age artefacts in Hungary – Lehetőségek és korlátok a bronztárgyak modern műszeres vizsgálatában Magyarországon. Archaeometriai Műhely 16 (2019) 1–12.

- Szathmári, I., Maróti, B., Tarbay, J. G., Kiss, V.: Bronzkori arany hajkarika leletek vizsgálatáról a Magyar Nemzeti Múzeum gyűjteményéből. In: Bartosiewicz L., T. Biró K., Sümegi P., Törőcsik T. (szerk.): Mikroszkóppal, feltárásokkal, mintavételezéssel, kutatásokkal az archeometria, a geoarcheológia és a régészet szolgálatában. Tanulmányok Ilon Gábor régész 60 éves születésnapi köszöntésére. Szeged 2019, 291–315.